Wear Protection Resistant Stud

Extreme abrasion resistant studs with tungsten carbide and chromium carbide hardfacing for maximum equipment protection in harsh industrial environments.

Wear Resistant Hardfacing Studs

Engineered for extreme abrasion protection in the most demanding industrial applications where equipment faces constant wear and tear.

Superior Abrasion Protection for Critical Equipment

Our wear protection resistant studs are specifically designed to combat extreme abrasion in industrial environments. These hardfacing studs create a protective layer on equipment surfaces, dramatically extending service life and reducing downtime in mining, cement production, power generation, and heavy machinery applications.

With advanced materials including tungsten carbide and chromium carbide, our studs provide unmatched resistance to abrasion, impact, and corrosion. They are applied using stud welding technology for secure, permanent attachment to equipment surfaces.

Extreme Abrasion Resistance

Engineered to withstand the most severe wear conditions with tungsten carbide reinforcements.

Extreme Abrasion Resistance

Engineered to withstand the most severe wear conditions with tungsten carbide reinforcements.

Extreme Abrasion Resistance

Engineered to withstand the most severe wear conditions with tungsten carbide reinforcements.

Extreme Abrasion Resistance

Engineered to withstand the most severe wear conditions with tungsten carbide reinforcements.

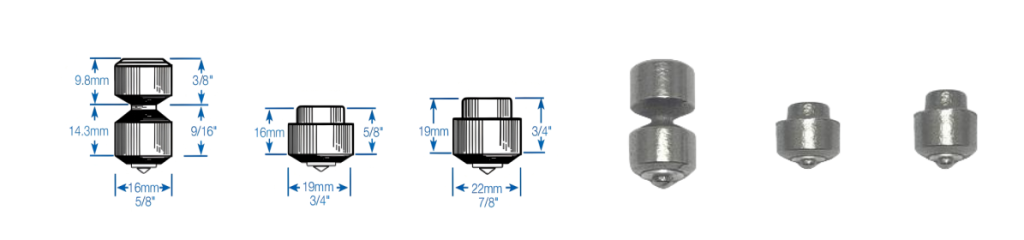

Stud Size | |||

Diameter | 16 mm (5/8 in) | 19 mm (3/4 in) | 22 mm (7/8 in) |

Height (as welded) | 10.9 mm (7/16 in) | 13 mm (1/2 in) | 16 mm (5/8 in) |

Welding Parameters | |||

Preheat | None required. Minimal during cold weather to remove condensation | ||

Position Capability | horizontal, vertical, overhead | horizontal, vertical | horizontal |

Power | 800 – 1000 A | 1000 – 1100 A | 1200 – 1400 A |

Timer | 0.60 – 0.70 s | 0.70 – 0.85 s | 0.85 – 1.0 s |

Application | |||

Rate (per hour typical) | 200 – 250 | 200 – 250 | 200 – 250 |

Coverage (per hour typical) | 0.13 – 0.17 m2 (1.4 – 1.8 ft2) | 0.185 0.24 m2 (2.0 2.6 ft2) | 0.26 0.325 m2 (2.8 3.5 ft2) |

Stud Spacing | |||

Normal Conditions | 1500 / m2 (140 / ft2) | 1075 / m2 (100 / ft2) | 750 / m2 (70 / ft2) |

Severe Conditions | 1590 / m2 (148 / ft2) | 1160 / m2 (108 / ft2) | 818 / m2 (76 / ft2) |

Packaging (includes ceramic ferrules) | |||

Quantity per Carton2 | 500 studs | 250 studs | 250 studs |

Coverage per Carton (typical) | 0.32 0.33 m2 (3.4 3.6 ft2) | 0.21 0.23 m2 (2.3 2.5 ft2) | 0.31 0.33 m2 (3.3 3.6 ft2) |

Carton Weight | 23 kg (50 lb) | 11 kg (24 lb) | 16 kg (35 lb) |

Minimum Order | 500 studs | 500 studs | 500 studs |

Material Options & Specifications

Choose from our range of wear resistant stud materials, each optimized for specific abrasion conditions and applications.

Tungsten Carbide Wear Studs

Tungsten carbide studs offer the highest level of abrasion resistance available. With a hardness exceeding 70 HRC, these studs are ideal for extreme wear applications involving silica, sand, and hard rock abrasion.

| Property | Value | Application Benefit |

|---|---|---|

| Hardness | 70-75 HRC | Superior resistance to cutting wear |

| Carbide Content | 60-70% by volume | Maximum abrasion protection |

| Impact Resistance | Good | Suitable for moderate impact conditions |

| Temperature Limit | 550°C (1022°F) | High-temperature applications |

| Recommended Applications | Mining shovel teeth, crusher liners, slurry pump casings, dredge cutter heads | |

Chromium Carbide Wear Studs

Chromium carbide studs provide excellent abrasion resistance combined with good corrosion resistance. Ideal for applications involving both wear and corrosive environments.

| Property | Value | Application Benefit |

|---|---|---|

| Hardness | 58-65 HRC | Excellent abrasion resistance |

| Chromium Content | 25-30% | Good corrosion resistance |

| Impact Resistance | Very Good | Suitable for high-impact conditions |

| Temperature Limit | 800°C (1472°F) | Excellent high-temperature performance |

| Recommended Applications | Cement kiln liners, pulverizer rolls, boiler tubes, fan blades in abrasive environments | |

Composite Hardfacing Studs

Composite hardfacing studs combine multiple hard materials in a ductile matrix for balanced wear resistance and toughness. Perfect for applications with varying wear conditions.

| Property | Value | Application Benefit |

|---|---|---|

| Hardness | 55-62 HRC | Good abrasion resistance |

| Matrix Type | Austenitic/Martensitic | Excellent crack resistance |

| Impact Resistance | Excellent | Withstands severe impact loading |

| Temperature Limit | 450°C (842°F) | Moderate temperature applications |

| Recommended Applications | Crusher hammers, mill liners, trencher teeth, loader buckets | |

Ceramic Enhanced Wear Studs

Ceramic enhanced studs incorporate ceramic particles for exceptional wear resistance in low-to-moderate impact applications. Excellent for sliding abrasion conditions.

| Property | Value | Application Benefit |

|---|---|---|

| Hardness | 65-72 HRC | Exceptional abrasion resistance |

| Ceramic Type | Alumina/Zirconia | Low friction coefficient |

| Impact Resistance | Moderate | Best for sliding/rolling abrasion |

| Temperature Limit | 1000°C (1832°F) | Extreme temperature capability |

| Recommended Applications | Chute liners, hoppers, conveyor systems, cyclone separators | |

Industrial Applications

Our wear protection resistant studs are used across multiple industries to protect critical equipment from abrasion damage.

Mining & Mineral Processing

Protect crusher liners, shovel teeth, hopper liners, and conveyor systems from extreme abrasion in ore processing. Mining wear parts that withstand constant rock-on-metal contact.

Cement & Aggregate Industry

Extend life of cement plant wear parts including kiln liners, preheaters, crusher hammers, and separator blades in high-temperature abrasive environments.

Power Generation

Protect boiler tubes, ash handling systems, pulverizer rolls, and fan blades in coal-fired and biomass power plants from erosive wear.

Heavy Equipment & Machinery

Increase service life of loader buckets, excavator teeth, bulldozer blades, and other earthmoving equipment wear parts subject to severe abrasion.

Benefits of Wear Resistant Studs

Dramatically increase the service life of expensive equipment components, reducing replacement frequency and capital expenditure.

Minimize equipment shutdowns for maintenance and component replacement, maximizing production uptime and operational efficiency.

Reduce overall operating expenses through fewer component replacements, less maintenance labor, and increased equipment availability.

Apply studs using standard stud welding equipment without dismantling equipment, allowing for quick in-field repairs and maintenance.

Wear Protection Resistant Studs

Optimized for search engines to help you find the best abrasion protection solutions