Hexmesh For Refractory Kilns Furnaces, Incinerators Lining

Hexmesh for Refractory Kilns, Furnaces, Incinerators Lining | High-Temp Industrial Solution

Hexmesh for Refractory Kilns, Furnaces, and Incinerators Lining,High-Temperature Industrial Solution

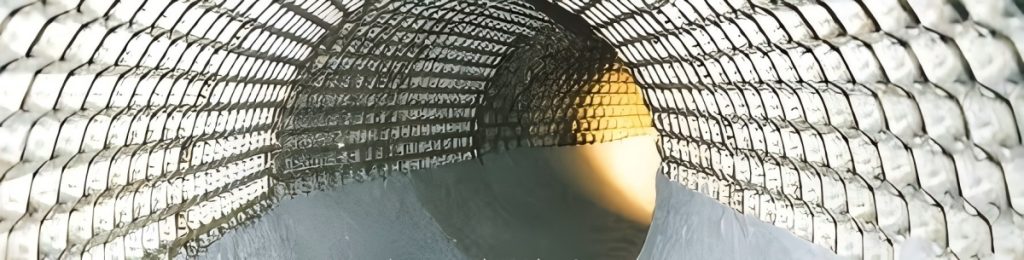

Hexmesh for refractory kilns, furnaces, and incinerators lining is a specialized industrial material engineered to strengthen and stabilize refractory linings in extreme high-temperature working environments. As a critical component in industrial thermal equipment, this refractory hexmesh effectively prevents refractory materials from cracking, spalling, and falling off, extending the service life of kilns, furnaces, and incinerators by 30% or more. Whether for cement kilns, steelmaking furnaces, or waste incinerators, our heat resistant hexmesh provides reliable structural support for refractory linings, ensuring stable equipment operation and reducing maintenance costs.

Core Advantages of Our Refractory Hexmesh

- Exceptional High-Temperature Resistance: Our refractory hexmesh can withstand continuous high temperatures ranging from 1200℃ to 1800℃, making it suitable for all types of high-temperature kilns, furnaces, and incinerators. The heat resistant performance ensures the hexmesh maintains its structural integrity even in long-term high-temperature operations, without deformation or failure.

- Superior Corrosion & Oxidation Resistance: Adapted to the harsh working environment of thermal equipment, the hexmesh resists corrosion from corrosive gases, dust, and molten materials generated during operation. The anti-oxidation coating on the surface enhances its resistance to high-temperature oxidation, further extending its service life.

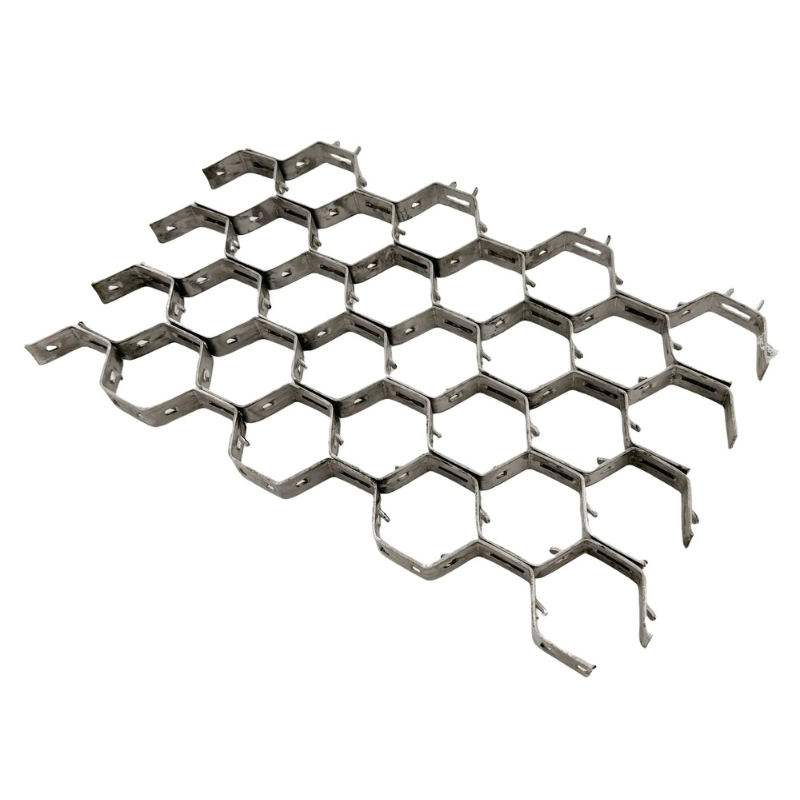

- Excellent Flexibility & Easy Installation: The flexible structure of the kiln lining hexmesh allows it to be easily cut, bent, and shaped according to the specific size and shape of the equipment’s inner lining. This flexibility greatly reduces installation difficulty and time, improving construction efficiency. No special installation tools are required, enabling quick on-site assembly.

- Strong Tensile Strength & Stability: Made of high-quality alloy materials, the refractory hexmesh has excellent tensile strength and load-bearing capacity. It can effectively disperse the thermal stress generated by temperature changes in the refractory lining, avoiding lining deformation and cracking, thus ensuring the stability of the entire thermal system.

- Long Durability & Cost-Effectiveness: With high-quality materials and advanced manufacturing processes, our hexmesh for incinerator lining has a long service life, reducing the frequency of replacement and maintenance. Lower maintenance costs and reduced equipment downtime bring significant economic benefits to enterprises.

Application Scenarios

Our refractory hexmesh is widely used in the lining reinforcement of various high-temperature industrial equipment, covering multiple industries such as building materials, metallurgy, environmental protection, and chemical engineering.

- For Refractory Kilns: Specifically designed for the inner lining reinforcement of cement kilns, lime kilns, ceramic kilns, and rotary kilns. The kiln lining hexmesh effectively resists the high-temperature erosion and mechanical wear of the lining during the kiln’s rotation, improving the structural stability of the refractory lining and reducing maintenance frequency. It is an essential material for ensuring the continuous and stable operation of kiln equipment.

- For Refractory Furnaces: Applied to the lining of industrial furnaces such as steelmaking furnaces, heating furnaces, heat treatment furnaces, and glass melting furnaces. In the high-temperature environment of furnaces, the furnace lining hexmesh disperses thermal stress, avoids lining deformation and spalling caused by rapid temperature changes, and ensures the safe operation of the furnace. It is suitable for various furnace types and operating conditions, providing reliable protection for furnace linings.

- For Incinerators: Ideal for the lining reinforcement of waste incinerators, medical waste incinerators, and hazardous waste incinerators. The incinerator lining hexmesh can adapt to the harsh environment of alternating high temperatures and corrosive waste gas, resisting the corrosion of acidic and alkaline gases and ensuring the safety and durability of the incinerator lining. It effectively solves the problem of frequent lining damage in incinerators, improving the operational efficiency of incineration equipment.

Technical Specifications

Parameter | Details |

|---|---|

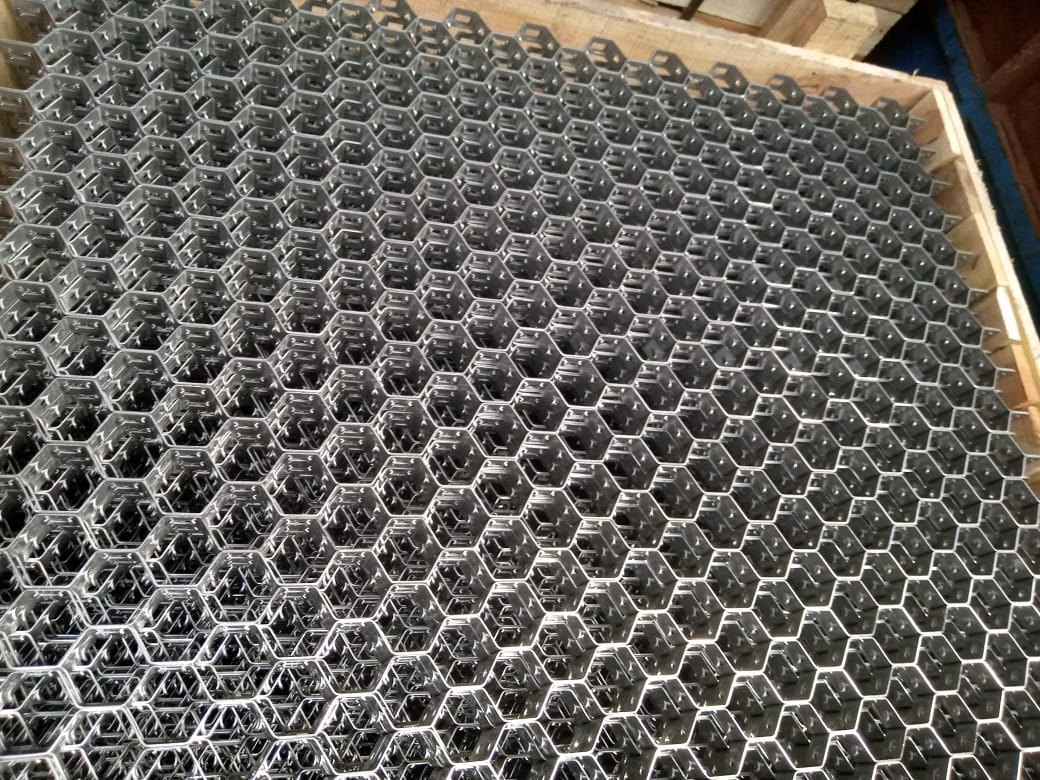

Material Options | Stainless Steel 304, Stainless Steel 310S, Nickel-chromium Alloy (Inconel 600/625, for higher temperature requirements) |

Mesh Size | 10x10mm, 20x20mm, 25x25mm, 30x30mm (customizable according to refractory lining requirements) |

Wire Diameter | 1.0mm-3.0mm (customizable based on load-bearing needs) |

Temperature Resistance | 1200℃-1800℃ (varies by material: 304 Stainless Steel: 1200℃; 310S Stainless Steel: 1400℃; Nickel-chromium Alloy: 1600℃-1800℃) |

Surface Treatment | Anti-oxidation coating, Passivation treatment |

Sheet Size | 1000x2000mm, 1220x2440mm (customizable in width and length) |

Tensile Strength | ≥500MPa (varies by material and wire diameter) |

Customization Services

We understand that different industrial equipment has unique requirements for refractory hexmesh. Therefore, we provide comprehensive customization services to meet your specific needs. Whether you need a specific material, mesh size, wire diameter, or sheet size, our professional team will work with you to develop the most suitable refractory hexmesh solution. We can also provide customized surface treatment processes according to the working environment of your equipment, ensuring the hexmesh achieves the best performance in your application scenario.

Frequently Asked Questions (FAQ)

- Q: What material of refractory hexmesh should I choose for my 1500℃ furnace? A: For a 1500℃ furnace, we recommend 310S stainless steel or nickel-chromium alloy refractory hexmesh. 310S stainless steel can withstand up to 1400℃, and nickel-chromium alloy can withstand 1600℃-1800℃, both of which can meet the high-temperature requirements of your furnace.

- Q: How to install the kiln lining hexmesh? A: The installation of kiln lining hexmesh is simple. First, cut the hexmesh into the required size according to the inner wall of the kiln. Then, fix the hexmesh on the inner wall of the kiln with anchor bolts or refractory nails. Finally, apply refractory castable or refractory brick on the surface of the hexmesh. No special installation tools are required, and on-site construction can be completed quickly.

- Q: What is the service life of your refractory hexmesh? A: The service life varies by material and application environment. Generally, 304 stainless steel hexmesh has a service life of 2-3 years, 310S stainless steel hexmesh has a service life of 3-5 years, and nickel-chromium alloy hexmesh has a service life of 5-8 years. Under proper use and maintenance conditions, the service life can be further extended.

- Q: Can you provide samples before bulk ordering? A: Yes, we provide free samples of refractory hexmesh. You can tell us your specific requirements (material, mesh size, etc.), and we will send the corresponding samples to you for testing and verification.