Nano-Microporous Ceramic Fiber Board For Steel Industry

Microporous panels for the steel industry are engineered for high-temperature applications, offering exceptional thermal efficiency with conductivity lower than still air. These advanced materials reduce heat loss and energy consumption, improve the working environment, and extend equipment lifespan. With a thinner insulation layer, they optimize space by increasing internal volume or reducing equipment size. Additionally, they minimize heat retention, enhancing the rate of temperature rise and overall operational efficiency.

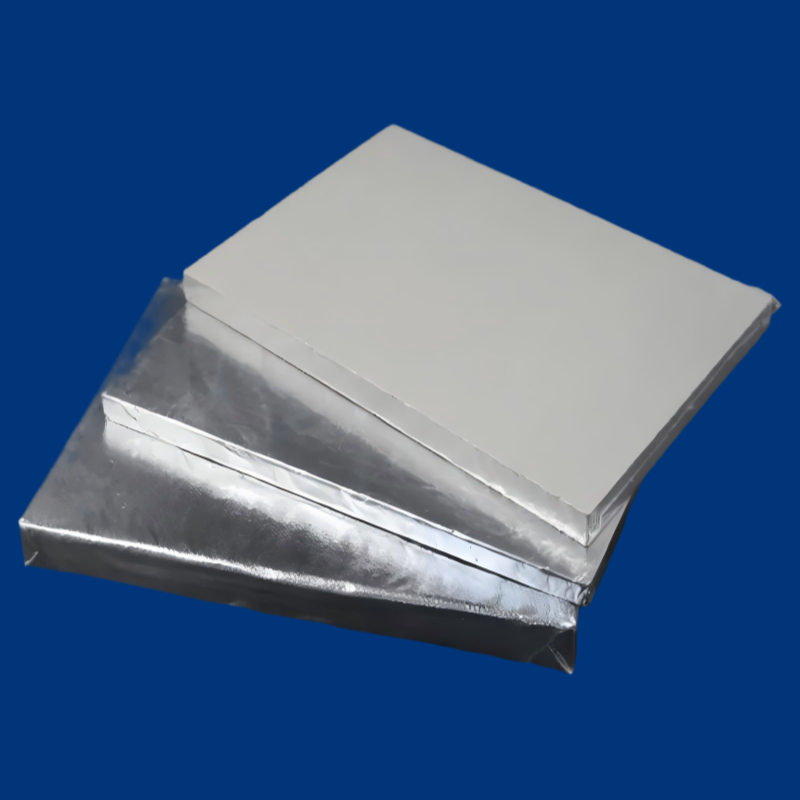

Introduction of Microporous Insulation Board

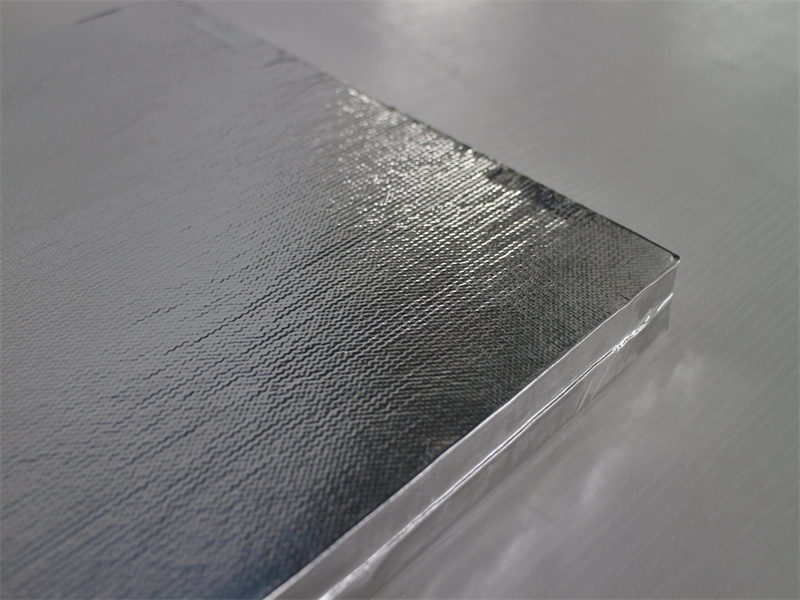

Microporous insulation panels represent a cutting-edge solution for the steel industry, offering exceptional thermal insulation performance based on microporous technology. Composed primarily of 7-12 nanometer silica, these panels form countless nano-scale pores that, along with highly effective infrared reflective materials, suppress heat transfer through conduction, convection, and radiation. With a thermal conductivity lower than still air, microporous panels outperform traditional materials by 3-6 times. This makes them one of the most efficient high-temperature insulation materials available today. Available in flat boards, rolls, blocks, and flexible mats, they are suitable for a variety of applications, including furnace walls and pipe systems in steel plants. Their reduced thickness allows for optimized space, lower energy costs, and improved equipment efficiency.

Features of Microporous Board / Panel

*Low Thermal Conductivity:

Microporous insulation materials provide 3-4 times better insulation than traditional materials, Thissignificantly reduces energy consumption, minimizes the thickness and weight of insulation layers,or increases the effective capacity of steel industry equipment.

*Superior Thermal Performance:

With low specific heat and heat storage capacity, these materials are highly resistant to thermalshock and can be used long-term without deterioration, as long as they aren’t physically damaged.

*Environmentally Friendly:

Free of harmful fibers, these insulation materials meet both domestic and internationalenvironmental standards, making them a safe choice for the steel industry.

*Non-Combustible:

These materials are fully non-flammable, providing added safety in high-temperature environmentslike steel production.